When uptime isn’t optional, an industrial generator is far more than a backup—it’s the heart of your facility’s power system. Designed for heavy-duty performance, an industrial generator is a high-capacity, three-phase power unit that supplies dependable electricity to large-scale operations such as factories, hospitals, data centers, and mining facilities. These machines are engineered to handle long runtimes, tough environments, and heavy motor loads—keeping production lines, life-safety systems, and mission-critical infrastructure running without interruption.

In this comprehensive 2025 guide, you’ll learn how industrial generators work, the main fuel types (diesel, natural gas, and bi-fuel), and how to size the right unit for your needs. We’ll also cover installation, compliance, total cost of ownership (TCO), and what to check before buying.

To keep things easy, we’ve included practical examples, formulas, and a vendor checklist—all explained in plain, everyday language.

What Is an Industrial Generator?

An industrial generator is a heavy-duty power system designed for large facilities that demand continuous, reliable electricity. Unlike residential or portable generators, which provide short-term backup for homes or small offices, industrial models are built for three-phase operation, higher voltages, and long duty cycles. They feature robust engines, reinforced alternators, and control systems engineered for round-the-clock performance in demanding conditions.

Power ratings for these machines typically start around 50 kW and can exceed multiple megawatts (MW). They can operate as standalone units or in paralleled banks for scalability, redundancy, and maintenance flexibility—allowing one unit to stay online while another undergoes service.

Industrial generators are categorized by duty cycle:

- Standby: For backup use during outages—common in hospitals, data centers, and healthcare facilities.

- Prime: Suited for variable loads and extended operations, such as construction sites and temporary camps.

- Continuous: Built for uninterrupted 24/7 service in remote utilities, mines, or production plants.

You’ll find these generators powering manufacturing lines, telecom networks, oil and gas fields, water treatment plants, and critical infrastructure—anywhere consistent, high-capacity electricity is non-negotiable.

How Industrial Generators Work

An industrial generator converts mechanical energy into electrical power through three key systems: the engine, alternator, and control system—each essential for stable, reliable operation in mission-critical environments.

1) Engine → Mechanical Torque

The process begins with the engine, powered by diesel or natural gas. Combustion turns the crankshaft, producing mechanical torque. Diesel engines use compression ignition for strong torque at low RPMs, perfect for heavy loads. Natural gas engines use spark ignition for quieter, cleaner performance. A governor maintains a steady speed to keep the output frequency at 50 or 60 Hz under varying loads.

2) Alternator → Electrical Power

The alternator transforms mechanical motion into electricity. As the rotor spins within the stator, it generates a magnetic field that induces alternating current (AC). The Automatic Voltage Regulator (AVR) stabilizes voltage during load changes. Engine speed—typically 1800 RPM for 60 Hz—directly affects output, ensuring precise power for sensitive sites like hospitals and data centers.

3) Controls & Protection

Modern generators use programmable logic controllers (PLC), ATS/switchgear, and sensors to track temperature, oil pressure, and fuel. Built-in safety systems automatically shut down the unit for issues like overspeed or low oil. Remote monitoring, alarms, and auto-start functions support seamless operation and meet NFPA 110 generator compliance for life-safety and critical systems.

Industrial Generator Types (Fuel, Configuration, Duty)

Industrial generators come in several configurations, each designed to meet specific operational demands, fuel preferences, and runtime goals. Understanding these differences helps facilities choose the right balance between performance, cost, and sustainability.

By Fuel

Diesel:

The backbone of industrial power, an industrial diesel generator delivers unmatched torque, reliability, and efficiency. It’s perfect for heavy motor loads, remote areas, and long-duration use. Diesel fuel is easy to store and transport, offering quick response under sudden load conditions. However, it requires routine maintenance and fuel management to prevent contamination.

Natural Gas:

A natural gas generator provides cleaner emissions and quieter operation—making it ideal for urban installations or areas with environmental restrictions. Connected directly to the local gas pipeline, it offers virtually unlimited runtime. While its transient response is slightly slower than diesel, it’s favored for cost stability and eco-friendly operation.

Bi-Fuel/Dual-Fuel:

This hybrid system starts on diesel for reliable ignition, then transitions to natural gas for continuous operation. It balances flexibility, cost savings, and reduced emissions—ideal for facilities seeking efficiency without compromising power.

HFO, Propane & Renewable Diesel (R-D):

These fuels are often used in niche or policy-driven applications, such as green energy programs or regions with specific emissions mandates.

By Configuration

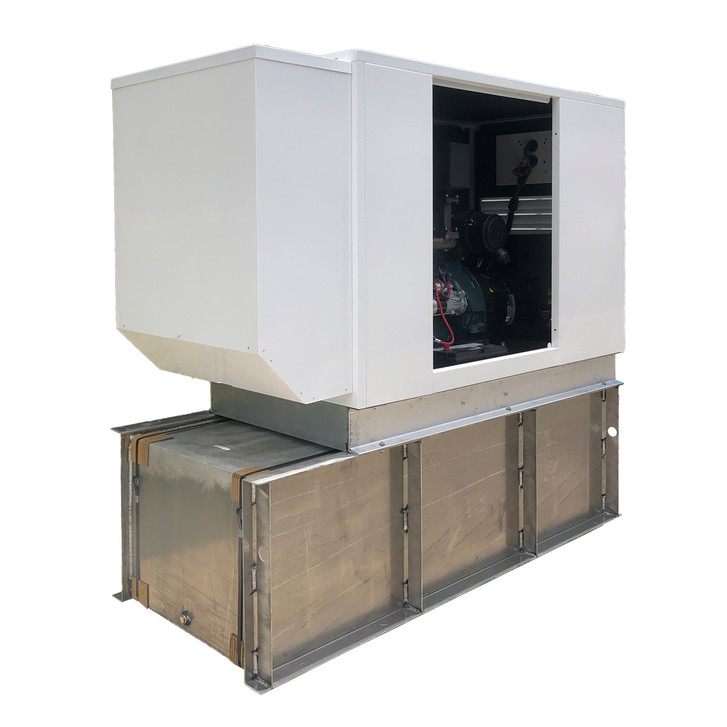

- Stationary Units: Permanent installations with weatherproof, sound-attenuated enclosures—common in factories and hospitals.

- Mobile Units: Trailered or containerized setups for temporary projects, construction sites, or event power.

- Paralleled Systems: Multiple generators synchronized for generator paralleling and N+1 redundancy, providing scalability, maintenance flexibility, and continuous uptime.

By Duty Rating

- Standby: Emergency-only systems, typically installed in hospitals or data centers under NFPA 110 generator standards.

- Prime/Continuous: Designed for ongoing or full-time operation, used in oilfields, mining camps, microgrids, or remote utilities.

Each type and configuration ensures your facility has the right level of resilience, performance, and compliance for its specific power needs.

Power Ratings & Sizing Method

Selecting the right industrial generator size is crucial for efficiency, reliability, and compliance with standards like ISO 8528. An accurately sized unit prevents overloads, maintains stability, and extends equipment life. Here’s how professionals determine the correct capacity through a structured process.

Load Audit

List all major electrical loads—HVAC, pumps, compressors, lighting, and IT systems. Record their running power in kilowatts (kW) to establish your facility’s baseline demand.

Starting Surges

Motors draw 2–6× their normal current when starting. To manage this, factor in surge watts or use soft starters and VFDs to minimize peak load.

Power Factor (PF)

Industrial systems typically run at PF ≈ 0.8, meaning real power (kW) equals 80% of apparent power (kVA). Convert using:

kW = kVA × PF or kVA = kW / PF.

Derating & Conditions

Adjust for altitude, high temperature, or fuel quality—these reduce generator performance. Derating ensures consistent output under actual site conditions.

Headroom & Redundancy

Operate at 70–80% of rated load to avoid underloading and improve fuel efficiency. For mission-critical applications, use N+1 redundancy to maintain uptime during maintenance or sudden demand spikes.

This method ensures your generator performs efficiently, safely, and reliably under real-world conditions.

Example: Manufacturing Facility Sizing

Consider a mid-sized manufacturing plant with a 160 kW running load and 220 kW peak demand. The site operates two 40 HP air compressors with soft starters, reducing inrush current. After a 5% derate for high ambient temperature, the load adjusts to 230 kW. Adding a 25% buffer for stability and future growth brings the total to about 288 kW. In this case, a 300 kW industrial generator is ideal for single-unit use. For facilities needing continuous uptime, two 175 kW units in parallel (N+1 configuration) provide scalability, easier maintenance, and uninterrupted power even during servicing.

This balanced approach ensures your generator runs efficiently, reliably, and safely under all conditions.

Industry Applications & Selection Notes

Each industry has unique power needs, and selecting the right industrial generator means balancing reliability, compliance, and performance. Whether for hospitals or heavy industry, the right system keeps critical operations running when utility power fails.

Hospitals & Clinics

Healthcare facilities need absolute reliability. NFPA 110 generators meet Level 1 Emergency Power Supply (EPS) standards, transferring automatically within 10 seconds of an outage. Systems typically include ATS/switchgear integration and fuel tanks providing 24–72 hours of backup for life-safety systems.

Data Centers & IT Facilities

Data centers depend on ISO 8528 Class G3-certified generators for fast response and stable performance. Paralleling systems with UPS integration ensure seamless transitions and continuous uptime during load changes.

Manufacturing & Industrial Plants

Facilities running PLCs, CNCs, and high-torque motors need precise voltage and frequency control. A steady industrial diesel generator prevents disruptions and protects sensitive machinery.

Mining, Oil & Gas

Rugged field operations require prime-duty, containerized generators built to handle dust, vibration, and heat. Remote monitoring and fuel tracking improve reliability in long-term use.

Water & Wastewater Treatment

These systems face heavy pump loads and moisture exposure. Corrosion-resistant enclosures and high inrush handling ensure durability and consistent power.

Telecom & Remote Sites

Compact generators with telemetry, remote diagnostics, and anti-theft protection are essential for isolated or unmanned installations.

Construction & Events

Mobile, sound-attenuated generators with quick-connect ATS/switchgear options offer temporary, reliable power where flexibility and noise reduction matter most.

Each industry requires a tailored approach to ensure uptime, compliance, and operational safety.

Emissions, Codes & Standards

Compliance is central to every industrial generator installation. Beyond performance, it ensures safety, environmental responsibility, and long-term reliability. Each unit must meet local, national, and international standards for emissions, noise, and operational safety.

EPA Tiers & EU Stage V

In the U.S., EPA Tier standards classify diesel emissions from Tier 1 to Tier 4. Most modern industrial diesel generators meet Tier 4 requirements, using Ultra-Low Sulfur Diesel (ULSD) and advanced systems like SCR or DPF filters to cut pollutants. Europe’s EU Stage V follows similar limits on particulate and NOx emissions.

NFPA 110

This standard governs emergency power systems for hospitals and safety-critical sites.NFPA 110 generators must start automatically and transfer power within 10 seconds to maintain continuous life-safety operations.

UL 2200 & ISO 8528

UL 2200 certifies mechanical and electrical safety, while ISO 8528 sets standards for performance, including voltage regulation, frequency stability, and transient response—vital for data centers and industrial automation.

IEEE 1547

This governs interconnection and performance of grid-tied or microgrid generator paralleling systems, ensuring smooth synchronization and power quality.

NFPA 30 & Local Codes

NFPA 30 regulates generator fuel tanks, spill containment, and flammable liquid storage. Local jurisdictions may add rules for noise control, setbacks, and environmental permitting.

Before purchasing, always request emission certificates, compliance documentation, and factory test reports to verify your generator meets all required standards.

Installation & Site Planning

Proper installation is key to the performance, safety, and compliance of any industrial generator. Whether used in hospitals, data centers, or manufacturing plants, planning must cover ventilation, fuel storage, electrical integration, and noise control to ensure reliability and meet regulations.

Placement & Ventilation

An industrial generator may be installed outdoors on a concrete pad or indoors in a mechanical or electrical room. Outdoor units often include weatherproof, sound-attenuated enclosures, while indoor setups need dedicated ventilation and exhaust routing. Balanced airflow is crucial for cooling and combustion, with louvers and automatic dampers helping manage intake and discharge air. Exhaust lines must minimize backpressure and safely vent radiator heat.

Fuel System Design

A dependable generator fuel system uses a main storage tank and a day tank feeding the engine. Double-wall containment, leak detection, and fuel filtration prevent contamination and extend fuel life. Following NFPA 30 and EPA rules for venting, spill prevention, and containment ensures compliance. Refueling access and storage should support 24–72 hours of autonomy and meet local fire and environmental codes.

Electrical Integration

Electrical setup includes rated ATS/switchgear, breakers, and grounding. The automatic transfer switch (ATS) manages seamless transitions when utility power fails. Proper design considers cable sizing, neutral bonding, and short-circuit protection, with coordination between inspectors and utilities for compliant installation.

Noise & Vibration Control

Industrial generators typically produce 70–75 dB(A) at 7 meters. Using vibration isolators, acoustic barriers, and sound-attenuated enclosures keeps noise low—especially important for hospitals, schools, or urban sites.

Thoughtful installation planning enhances performance, reduces downtime, and ensures long-term generator reliability under any operating condition.

Controls, Paralleling & Microgrids

Modern industrial generators use paralleling to boost scalability, reliability, and efficiency. Multiple units share loads, reduce downtime, and allow maintenance without interrupting operations.

Synchronization & Control

Before connecting in parallel, generators must align in voltage, frequency, and phase before connection. Electronic governors (droop or isochronous) maintain a steady 50/60 Hz, while synchronizers balance loads across units. Advanced ATS/switchgear with closed-transition transfer ensures seamless power shifts for critical sites like hospitals and data centers.

Monitoring & Integration

Integration with SCADA or Building Management Systems (BMS) provides full remote visibility—tracking load, fuel, temperature, and alarms in real time. These systems can trigger automatic load bank testing, schedule maintenance, and optimize fuel consumption.

Microgrids & Hybrid Power

Today’s hybrid microgrids blend solar PV, battery storage, and industrial diesel or natural gas generators. These integrated setups support demand response, grid independence, and energy efficiency—offering resilient, smart power solutions for industries that need both sustainability and uptime.

Fuel Use, Runtime & Autonomy

Efficient fuel management keeps an industrial generator dependable during long operations or grid outages. Fuel use, measured in liters per hour (L/hr), varies with load—typically shown at 25%, 50%, 75%, and 100%—helping operators plan accurate runtimes.

Diesel Generators

An industrial diesel generator is ideal for extended runtime needs, often supporting 24–72 hours of continuous power. Fuel should be stored in sealed generator fuel tanks with filtration, polishing, and leak detection. Rotate fuel every 6–12 months and use additives to prevent oxidation or microbial growth (“diesel bug”).

Natural Gas Generators

A natural gas generator offers continuous fuel via pipelines, removing refueling concerns. However, ensure gas supply and pressure remain stable, especially during emergencies or peak demand.

Proper planning for fuel autonomy, runtime monitoring, and tank management ensures reliable generator performance and uninterrupted operation when the grid goes dark.

Maintenance & Reliability Program

The dependability of an industrial generator comes down to consistent, disciplined maintenance. A structured program prevents breakdowns and ensures compliance with NFPA 110 and ISO 8528 standards for long-term reliability.

Preventive Service

Routine service—oil and filter changes, coolant checks, and air/fuel filter replacements—keeps components clean, lubricated, and efficient. Following manufacturer schedules helps avoid wear and ensures peak performance.

Battery & Block Heaters

Cold weather affects startup performance. Equipped battery chargers and block heaters keep the generator ready for immediate operation, even in freezing conditions.

Exercise & Load Bank Testing

Regular testing proves reliability. Monthly exercise runs and annual load bank tests confirm the generator can handle rated output, prevent wet stacking, and verify both engine and alternator performance.

Condition Monitoring & Service Contracts

Modern systems use vibration sensors, oil analysis, and coolant testing to detect early issues. A service-level agreement (SLA) ensures expert support, spare parts, and timely intervention.

A proactive maintenance program keeps your industrial generator running 24/7—because reliability isn’t chance, it’s consistent care.

Costs & Total Cost of Ownership (TCO)

Understanding the total cost of ownership (TCO) of an industrial generator is essential for smart budgeting and long-term reliability. While upfront CapEx grabs attention, the real value lies in balancing purchase, installation, and ongoing OpEx across the generator’s lifespan.

CapEx Factors

Initial costs depend on brand reputation, power rating, fuel type, and enclosure design. Features like EPA Tier/EU Stage compliance, advanced ATS/switchgear, and integration complexity also affect pricing. Premium brands may cost more upfront but typically offer greater reliability, support, and resale value.

Installed Costs

Installation includes site prep, pad construction, cabling, fuel line setup, and permits. Depending on size and setup, installation can add 25–40% to the project. Proper engineering ensures compliance and prevents costly rework later.

Operational Costs (OpEx)

Ongoing costs include fuel, preventive maintenance, remote monitoring, and load bank testing. Industrial diesel generators may use more fuel but often have lower maintenance costs than natural gas units, which benefit from a continuous pipeline supply.

TCO Insight & ROI Example

A thoughtful TCO approach compares one large generator against generator paralleling multiple smaller units. Paralleled systems can deliver better N+1 redundancy, flexibility, and uptime. For example, avoiding even one 8-hour production loss in a manufacturing facility can pay back the generator investment several times over—making reliability not just an expense, but an ROI asset. (≈280 words)

Vendor Comparison & Buying Checklist

Choosing the right vendor for your industrial generator is about more than just price—it’s about reliability, compliance, and long-term partnership. A structured comparison helps ensure your investment delivers consistent power, easy maintenance, and dependable support.

Key Specs to Compare

When evaluating potential suppliers, look beyond marketing claims. Focus on:

- Rated Output (kW/kVA): Confirm the generator’s real capacity and match it to your load profile.

- Voltage & Phase Options: Ensure compatibility with your facility’s electrical system.

- Transient Response Class: Verify performance per ISO 8528 standards, especially for motor-heavy or sensitive loads.

- Alternator & Controller Brands: Recognized names like Stamford, Leroy Somer, or Deep Sea offer proven reliability and support.

- Noise Level & Enclosure: Sound-attenuated housings and robust enclosures are essential for noise control and durability.

- Generator Fuel Tank & Runtime: Check fuel capacity, runtime at 50–75% load, and emission tier compliance (EPA or EU).

- Warranty & Local Service: Ensure quick parts access, trained technicians, and guaranteed response times.

Questions to Ask Vendors

- Can the system be expanded or integrated into generator paralleling or N+1 redundancy setups?

- What are the ambient limits and derating factors?

- How long is delivery, commissioning, and testing?

- Is factory training, documentation, and ongoing support included?

A transparent, side-by-side comparison ensures a code-compliant, efficient, and cost-predictable solution—maximizing uptime and total value across the generator’s lifecycle.

FAQs

Q. What will a 20,000 kW generator run?

A 20 MW industrial generator is an immense power source—capable of supplying electricity for a large industrial complex, mining operation, or data center hall. Depending on your power factor (typically 0.8 for motor-heavy systems) and load simultaneity, it can support hundreds of heavy machines, HVAC systems, and IT infrastructure simultaneously. Some facilities even use multiple 20 MW units in generator paralleling configurations to create microgrids or maintain uptime through N+1 redundancy.

Q. Industrial vs. Commercial Generator—What’s the Difference?

An industrial generator differs from commercial units in scale, durability, and compliance standards. Industrial models deliver higher three-phase voltages (208V–13.8kV), feature rugged engine and alternator designs, and are built for prime or continuous duty cycles. They also adhere to strict safety and performance standards like NFPA 110 generator regulations for emergency systems and ISO 8528 for frequency and voltage stability. Commercial models, by contrast, are typically smaller, serving retail outlets, offices, or restaurants with shorter runtimes and lighter loads.

Q. How Long Can an Industrial Generator Run Continuously?

A prime-rated or continuous-duty industrial generator can operate around the clock—literally for weeks or months—if properly maintained and refueled. Regular oil and filter changes, load bank testing, and fuel system checks are essential to sustaining reliability. Standby-rated generators, however, are designed for shorter, emergency-based operation during power outages or scheduled maintenance windows.

Q. Diesel or Natural Gas for Industrial Use?

The choice between a diesel and natural gas generator depends on location, fuel logistics, and environmental priorities. Diesel generators provide superior torque, quick startup, and independence from pipeline supply—making them ideal for remote or rugged environments. Natural gas generators offer quieter performance, cleaner emissions, and longer runtimes due to constant fuel flow. Many facilities adopt bi-fuel systems, combining both for cost efficiency and operational flexibility.

Q. What Is N+1 and Why Use It?

N+1 redundancy means having one additional generator beyond what’s required to meet your full load (e.g., four needed, install five). This configuration ensures uninterrupted power during maintenance or unexpected equipment failure. It also simplifies load management, prevents downtime, and supports compliance for critical infrastructure like hospitals, data centers, and industrial plants—where power loss isn’t an option.

Next Steps & Request a Quote

Selecting the right industrial generator is about more than just capacity—it’s about strategy. You’re balancing fuel type, generator sizing, compliance, and the long-term total cost of ownership to protect uptime and efficiency. Always size for your peak demand, plan for N+1 redundancy, and establish a preventive maintenance plan early to maximize performance and lifespan.

Whether you’re powering a manufacturing plant, hospital, or remote operation, our experts can help you choose the best system for your needs. For personalized sizing guidance, installation planning, or a detailed quote on our latest models, contact us today and schedule a quick 20-minute consultation to discuss your project goals and power requirements.