If a blackout isn’t an option for your business, you need a reliable commercial generator ready for action. In this guide, we'll explain what it is, how it operates, how to choose the right size, the true cost of purchase and operation, and include a proven checklist for your decision.

Quick Answer: What Is a Commercial Generator?

A commercial generator is a reliable power solution designed to keep businesses operational during power outages or in areas without stable electricity. Whether it’s a retail store, hospital, data center, or construction site, these systems ensure essential equipment keeps running when the grid fails.

Types and Power Configurations:

- Fixed Units: Installed permanently for facilities that require constant readiness.

- Mobile Units: Portable designs ideal for construction sites, events, or temporary operations.

- Power Ratings:

- Single-phase (120/240 V): Suitable for small businesses or offices.

- Three-phase (208/480 V): Used for large buildings with heavy machinery or HVAC systems.

Operating Modes:

- Standby Mode: Automatically activates during an outage via an Automatic Transfer Switch (ATS).

- Prime/Continuous Mode: Provides consistent power for long-term or daily operations.

Unlike residential generators, commercial generators are engineered for demanding conditions—offering superior durability, advanced digital controls, high load capacity, and compliance with strict safety and emission standards. In short, they keep productivity steady and prevent costly downtime when reliability matters most.

How a Commercial Generator Works

A commercial generator converts fuel into electrical energy through a combination of mechanical motion, magnetic induction, and intelligent control systems. Here’s a clear breakdown of how each part works together to keep your business powered:

1. Engine → Torque

At the heart of the generator is the engine, typically powered by diesel or natural gas/LP. It burns fuel to create mechanical energy, spinning the generator’s rotor. A built-in governor maintains a consistent 50 or 60 Hz frequency, even when electrical loads change. When heavy equipment or motors start, the engine instantly increases torque to stabilize the output. Without this control, voltage fluctuations could damage connected systems or cause shutdowns.

2. Alternator → AC Power

The alternator converts that mechanical energy into alternating current (AC). Its rotor and stator work together through electromagnetic induction, while an Automatic Voltage Regulator (AVR) constantly adjusts excitation to keep voltage steady during load variations—ensuring smooth performance for lighting, motors, and sensitive electronics.

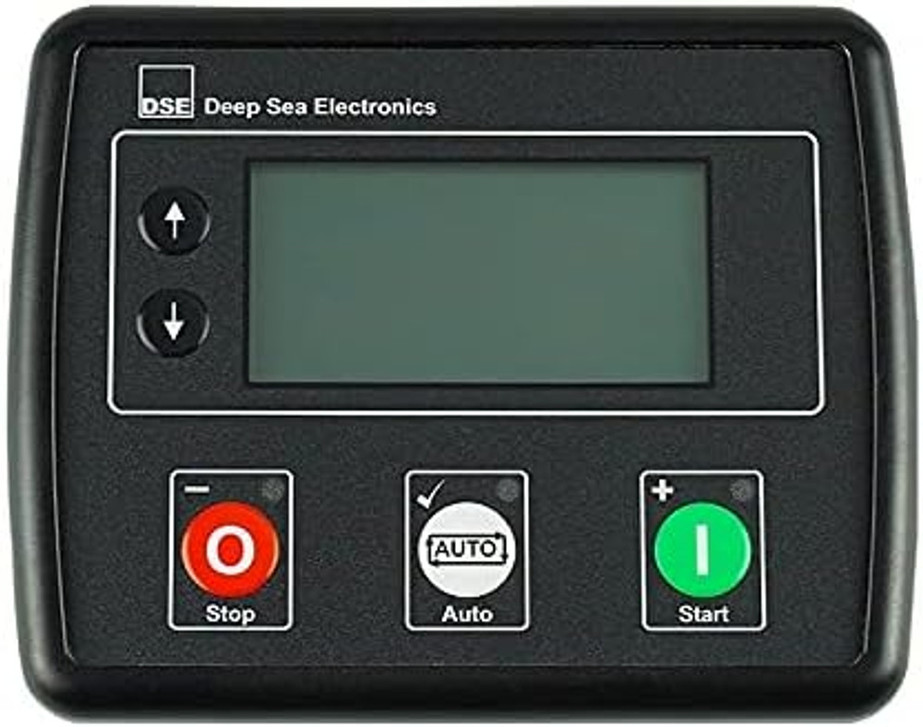

3. Brains & Safety Systems

A digital controller automates startup and shutdown, monitors temperature, pressure, and battery health, and runs scheduled test cycles. The Automatic Transfer Switch (ATS) shifts power from the utility to generator within seconds during outages, while built-in interlocks and sensors protect against overloads, faults, and fuel issues.

Commercial Use Cases & Typical Ranges

Every business has unique power needs, and the right commercial generator depends on the type of operations, equipment load, and runtime expectations. Here’s how power requirements typically align across industries:

- Restaurants & Cafés (15–80 kW):

These establishments rely on generators to power refrigeration units, ovens, mixers, and HVAC systems. A reliable generator prevents food spoilage, keeps kitchens running, and maintains a comfortable dining environment during outages. - Retail Stores & Offices (20–100 kW):

Essential for lighting, HVAC, and IT systems such as POS terminals and servers. Consistent power ensures uninterrupted sales and prevents data loss in office settings. - Clinics & Urgent Care Facilities (40–150 kW):

Medical sites depend on generators for critical equipment, lighting, and climate control. Units must meet NFPA 110 standards for life-safety compliance and seamless automatic switching. - Warehouses & Cold Storage (60–300 kW):

Large compressors, refrigeration systems, and conveyor belts require high starting torque. A robust generator prevents inventory loss and operational downtime. - Construction Sites & Outdoor Events (20–200 kW):

Mobile generators power tools, lighting towers, and audio systems where grid access is limited. They’re rugged, easy to transport, and essential for temporary power setups. - Telecom Facilities & Water Plants (30–150 kW):

Generators sustain pump motors, servers, and critical communications systems, handling high inrush currents reliably.

Note: Actual sizing depends on simultaneous equipment usage, startup surges, and anticipated future expansion. Always consult a professional to match generator capacity with real-world load profiles.

Fuel & Configuration Options

Choosing the right fuel type and configuration for a commercial generator impacts performance, reliability, and long-term operating costs. Each option has distinct advantages depending on availability, environment, and power demand. Here’s how they compare:

Diesel

Diesel generators remain the most common choice for commercial use due to their high torque output and efficiency per kWh. They deliver exceptional starting power, making them ideal for motor-driven loads such as compressors, pumps, and HVAC systems. Diesel also offers strong energy density and easier fuel logistics, allowing on-site storage for extended runtime. However, proper fuel handling, filtration, and periodic testing are crucial to prevent fuel degradation. Modern diesel generators must also comply with strict emission standards (EPA Tier 3/4), requiring ultra-low sulfur diesel (ULSD) and upgraded exhaust systems to minimize pollutants.

Natural Gas

Natural gas generators are valued for their cleaner emissions, quiet operation, and continuous supply through utility pipelines. They’re perfect for businesses connected to municipal gas systems, eliminating the need for fuel deliveries. Although slightly slower in transient response than diesel during sudden load changes, their reduced operating costs and environmental benefits make them an excellent choice for urban or eco-conscious operations. Before installation, confirm the meter size and regulator capacity to ensure sufficient gas flow for peak loads.

LP / Propane

Propane (LP) is ideal in locations without natural gas infrastructure. It provides stable combustion and long shelf life, making it reliable for standby applications. Since propane vaporizes poorly in freezing temperatures, adequate tank size and placement are critical in cold climates. Generators require on-site tank storage, usually refueled by local suppliers.

Bi-Fuel / Dual-Fuel

Dual-fuel generators start on diesel and then transition to run primarily on natural gas, combining performance with cost efficiency. This configuration improves runtime flexibility, allowing operations to switch fuels based on availability or price. It’s a great solution for facilities wanting diesel reliability with the cleaner emissions of gas systems.

Stationary vs Mobile

Stationary generators are fixed installations enclosed in weather-resistant housings, often with base fuel tanks for long-term use. They suit facilities like hospitals, data centers, or warehouses. Mobile generators, on the other hand, are trailer- or container-mounted units equipped with cam-lock panels, making them easy to transport and ideal for construction sites, outdoor events, or disaster relief operations.

Duty Rating: Standby vs Prime

Standby generators serve as emergency power sources, running only during utility outages and typically for limited hours per year. Prime or continuous-duty generators are built for daily or extended operation, common on remote job sites or industrial setups. This rating affects engine design, fuel system capacity, service intervals, and warranty terms—making proper selection essential for reliable performance.

Sizing a Commercial Generator (Step-by-Step)

Choosing the right commercial generator isn’t just about picking a large unit—it’s about finding the perfect match between your business’s electrical demand and the generator’s rated capacity. The right size ensures efficiency, reliability, and cost-effectiveness. Follow this structured, step-by-step approach to get accurate sizing every time:

1. List All Electrical Loads

Start by listing every circuit and device that will draw power from the generator—HVAC systems, pumps, refrigeration units, IT servers, elevators, and lighting. Record their running wattage in kilowatts (kW) or kilovolt-amperes (kVA). This gives you the baseline for total running load.

2. Account for Starting Surges (LRA)

Electric motors often draw a locked-rotor current (LRA) of 2–6 times their running load when starting. If ignored, these short bursts can overload a generator or cause voltage drops. Use soft starters or variable frequency drives (VFDs) to reduce surge impact and stabilize startup loads.

3. Consider Simultaneity and Diversity

Not all systems operate together. For example, your HVAC may cycle off while lighting and computers stay on. Apply diversity factors—estimating what runs simultaneously versus intermittently—to prevent overestimating capacity and inflating generator size unnecessarily.

4. Understand kW, kVA, and Power Factor (PF)

Generators are rated in both kW (real power) and kVA (apparent power). The difference is determined by the power factor (PF), typically 0.8 for commercial, motor-heavy environments.

[ kW = \frac{V × A × PF}{1000}, \quad kVA = \frac{kW}{PF} ]

Knowing this helps align generator output with actual electrical performance.

5. Account for Derating

Environmental conditions—like altitude, temperature, and fuel type—can affect generator output. For example, high elevations reduce air density, which impacts engine combustion. Always check manufacturer derating charts to maintain accurate sizing.

6. Leave Headroom for Growth

Your generator should typically operate at 70–80% load, leaving 20–30% spare capacity to handle surges, load growth, or expansion. This margin keeps performance stable and prolongs engine life.

7. Match Voltage and Phase

Verify your facility’s setup—single-phase (120/240 V) for smaller operations or three-phase (208/120 V or 480/277 V) for larger ones. The correct phase ensures balanced distribution and prevents equipment damage.

Example Sizing Scenarios:

- 100-seat restaurant: 35 kW running load; surges bring total to 50–60 kW.

- Three-story office: 80 kW running; elevator adds surge → 120–150 kW total.

For accurate planning, use the Generator Load Calculator, Standby Generator Sizing Calculator, or explore models like the 30 kW Diesel Generator for real-world comparisons.

Switchgear, ATS & Power Quality

A commercial generator is only as effective as the switchgear and transfer systems supporting it. These components manage how power transitions between the utility grid and generator, ensuring smooth and reliable performance.

- ATS Types: The Automatic Transfer Switch (ATS) is the bridge between utility and generator power. It comes in two main forms: service-rated ATS units, which can function as the primary disconnect, and non-service-rated ones used in secondary circuits. Transitions can be open (break-before-make) or closed (make-before-break) depending on the load’s sensitivity. Advanced bypass-isolation designs allow maintenance without interrupting power—ideal for hospitals and data centers.

- UPS/IT Integration: For facilities with sensitive electronics or data systems, coordination with Uninterruptible Power Supplies (UPS) is crucial. Following ISO 8528 transient response standards helps maintain consistent voltage and frequency during transfer, preventing IT equipment from resetting or shutting down.

- Load Management: Smart delay modules can stagger startup of large motors, HVAC, and pumps—allowing a smaller generator to handle higher loads more efficiently.

- Key Measurements: Always monitor sound level (dB(A) @ 7m), THD (total harmonic distortion), and voltage/frequency regulation to maintain optimal power quality and protect critical systems.

Installation, Codes & Compliance

Proper installation is what transforms a commercial generator from a machine into a dependable power system. Meeting local codes, safety standards, and engineering guidelines ensures long-term performance and legal compliance.

Permits & Inspections: Always comply with your local Authority Having Jurisdiction (AHJ). This includes electrical permits, load testing, and inspection approvals before commissioning. Professional installation guarantees both safety and warranty validity.

Emissions: Commercial generators must meet environmental regulations such as EPA Tier or EU Stage standards. Diesel units require Ultra-Low Sulfur Diesel (ULSD), while natural gas systems must meet local air quality codes. These ensure reduced emissions and cleaner operation.

Standards: Verify compliance with key industry codes—UL 2200 for generator safety, NFPA 110 for life-safety systems, and NFPA 30 for fuel storage. Local jurisdictions may also impose noise and setback restrictions.

Location & Ventilation: Ensure proper airflow, radiator discharge, and exhaust routing. Generators can be installed indoors (in technical rooms) or outdoors on reinforced pads with adequate clearance for cooling.

Fuel Systems: Choose between base or day tanks with secondary containment. Consider fuel-polishing systems to prevent contamination during long storage periods.

Noise & Vibration Control: Use attenuated enclosures, vibration isolators, and sound barriers for quieter operation.

Seismic & Wind Resistance: Anchor the system to meet regional seismic and wind-load standards. Proper installation guarantees a safe, compliant, and long-lasting generator system.

Runtime & Fuel Planning

Diesel: Diesel generators remain a top choice for businesses that need long, uninterrupted runtime. Tanks should be sized for 24 to 72 hours of operation, depending on how critical your application is. Use 50–75% load consumption curves to calculate exact fuel requirements and ensure proper storage with filtration to prevent contamination.

Natural Gas: Ideal for facilities with utility connections, natural gas provides a continuous fuel supply and eliminates refueling downtime. Always verify the available BTU/hr from your gas line to meet your generator’s rated load. Create a contingency plan for potential gas-line interruptions, such as having a secondary fuel source or an on-site backup generator.

Propane: Propane systems work well in remote or rural areas without natural gas infrastructure. However, confirm that the tank’s vaporization capacity is sufficient in cold temperatures. Plan for delivery schedules, refill logistics, and adequate on-site storage to ensure consistent performance.

Thoughtful fuel planning keeps your commercial generator dependable when the grid goes down.

Maintenance Program & Reliability

A well-structured maintenance program is the foundation of long-term reliability for any commercial generator. Routine care not only extends equipment life but also ensures that power is ready when you need it most.

- Preventive Maintenance: Regular maintenance includes oil and filter changes, coolant checks, and replacement of air and fuel filters. These steps prevent buildup, corrosion, and overheating—key issues that can cause generator failure.

- Battery & Block Heaters: Cold weather can reduce battery performance, so maintaining battery voltage and using engine block heaters ensures reliable starts in low temperatures.

- Monthly Exercise & Load-Bank Testing: Running the generator monthly under load keeps internal parts lubricated and prevents wet stacking (fuel residue buildup). Conduct a full load-bank test annually to confirm system performance and engine health.

- Telemetry & Alerts: Modern generators include remote monitoring systems that track performance, fuel levels, and fault codes in real time. Pair this with a strong service-level agreement (SLA) and readily available spare parts kits for minimal downtime.

- Reliability Metrics: Track indicators such as MTBF (Mean Time Between Failures) and MTTR (Mean Time to Repair) to measure dependability and refine maintenance schedules. A proactive program ensures your generator is always mission-ready.

New vs Used vs Rental

When investing in a commercial generator, selecting between new, used, or rental options depends on your budget, runtime requirements, and long-term plans. Each option has its own advantages and trade-offs.

- New: Purchasing a new generator offers the peace of mind of a full manufacturer's warranty, the latest emission-compliant technology, and advanced digital controls for monitoring and efficiency. It’s ideal for businesses needing long-term, mission-critical backup power with predictable performance and support.

- Used/Reconditioned: A used or reconditioned generator can significantly reduce upfront costs (CapEx) while still providing solid reliability. Always review run hours, load-test results, and service history to confirm performance. Reputable resellers like Depco Power Systems often refurbish units to near-new standards with updated components and verified output.

- Rental/Leasing: Best for temporary projects, seasonal operations, or construction bridge power. Rentals eliminate maintenance responsibility but come with higher operational costs. Always compare the total cost per kWh/month to ensure cost-effectiveness.

Choose the ownership model that aligns with your business’s power demands and financial strategy.

Costs & Total Cost of Ownership (TCO)

Understanding the Total Cost of Ownership (TCO) of a commercial generator helps businesses make smarter investment decisions beyond the upfront purchase price. The true cost involves installation, operation, and the financial impact of downtime.

- Price Drivers: The overall price depends on several factors, including kW rating, fuel type, acoustic enclosure, ATS/switchgear, paralleling capability, tank size, and regulatory compliance. Features like low-noise housing or advanced automation can increase cost but also improve efficiency and reliability.

- Installed Cost: Installation typically includes building the concrete site pad, crane placement, electrical connections, fuel line setup, and permits. Acoustic work or custom enclosures may add to the total project cost.

- Operational Costs (OpEx): Ongoing expenses include fuel consumption, preventive maintenance, load testing, and remote monitoring. These recurring costs often determine the system’s affordability over its lifecycle.

- TCO Framework: Businesses must decide between a single large generator or multiple smaller units in parallel, weighing uptime, service scheduling, and redundancy. Also, calculate the cost of downtime—from lost productivity to spoiled inventory or contract penalties.

- ROI Example: Avoiding a 4–8 hour power outage at a retail store with frozen goods could prevent losses exceeding $50,000. That alone may justify investing in a high-quality commercial generator.

Assess total value by combining installed cost + OpEx + downtime savings.

Brand Landscape & How to Choose a Vendor

When investing in a commercial generator, the brand you choose directly affects reliability, serviceability, and long-term value. Leading manufacturers like Cummins, Caterpillar, Generac, and Kohler dominate the commercial market, offering proven track records in performance, emissions compliance, and global support networks. For projects needing mobility, high-end portable and trailer-mounted systems from these same brands or specialized OEMs are excellent alternatives.

What matters most is service accessibility—a strong local dealer network, readily available spare parts, and fast response times during outages. Also, review factory test reports, maintenance documentation, and technician certifications to confirm the vendor’s expertise. These indicators reflect how well your provider can support you beyond installation.

Always request specification comparison sheets covering kW/kVA ratings, transient response, noise levels, fuel tank size, and control features. A reputable vendor should act as your long-term power partner, not just a seller—helping ensure uptime, safety, and consistent generator performance for years to come.

Buyer’s Checklist (Actionable)

Before purchasing a commercial generator, use this quick checklist to confirm you’re choosing the right system:

- Power rating (kW/kVA), voltage/phase, and duty rating suitable for your operations.

- Starting capacity and Automatic Voltage Regulator (AVR) for smooth performance.

- Fuel type, availability, and delivery logistics.

- Enclosure type and sound level (dB(A)) to meet local noise limits.

- ATS type and transition mode for seamless power transfer.

- Fuel tank capacity and runtime @ 50–75% load for adequate endurance.

- Certifications and emissions compliance per local regulations.

- Warranty, service SLA, and spare parts availability.

- Complete documentation, including as-built diagrams and factory test reports, to verify quality and performance.

FAQs

- What size generator for a restaurant?

A 100-seat restaurant needs about 35 kW running and 50–60 kW total with HVAC and refrigeration surges. - Diesel or natural gas—what’s better?

Diesel gives higher torque; natural gas is cleaner and pipeline-fed. Pick based on fuel access and emissions. - How long can it run?

Prime-rated units can run 24+ hours; standby models handle shorter periods. - Do I need an ATS?

Yes—an ATS automatically switches power during outages. - Can I parallel generators?

Yes, paralleling adds redundancy and flexibility. - What’s an acceptable noise level?

Keep it under 70 dB(A) at 7 m; use sound-attenuated enclosures in city zones.

Conclusion & Next Steps

Choosing the right commercial generator goes beyond upfront cost—it’s about matching fuel type, load-based sizing, regulatory compliance, and total cost of ownership (TCO) to your business’s needs. Evaluate performance, maintenance, and reliability before deciding. For personalized guidance or to explore options, contact our team to discuss your project and find the perfect power solution for your facility.